Tesla is building them, Honda is building them, Vancouver’s Sanctuary AI is building them -- humanoid robots, that is.

There are probably at least a dozen companies around the world currently developing humanoid robots, and many more companies either using or developing industrial robots.

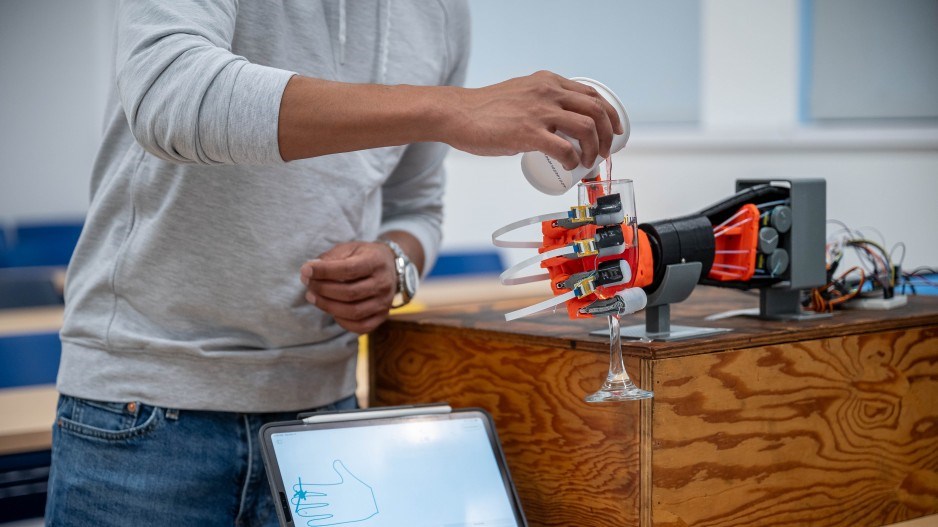

But what many of these robots lack is that tender human touch, which means they lack sensitivity and dexterity.

Researchers at the University of BC, working with researchers at Honda, say they have made a breakthrough with the development of a “smart, stretchable and highly sensitive” type of rubber that is like human skin.

The breakthrough was recently reported on in Scientific Reports, and lead author Saquib Sarwar – who worked on the project for his PhD thesis and now works for lululemon as the company’ senior machine learning scientist – told BIV News there a number of potential applications and paths to commercialization.

“Imagine an Amazon fulfillment centre,” Sarwar said. “That would be a prime application for these sensors because in a fulfilment centre, you need thousands of pairs of hands to package things, and they’re already working on this automation. There are tons of these mass-scale, dexterous activities that require something like this.”

Honda’s interest in the robot skin is two-fold: Honda not only uses industrial robotics in its auto manufacturing plants, it also developed one of the first humanoid robots – Asimo – more than two decades ago.

Made from silicone rubber, which gives the material the kind of suppleness that human skin has, the material has sensors embedded in it that can give machines a kind of “touch” sensitivity, which can be useful for doing things that require some delicacy and dexterity, like picking up ripe fruit without damaging it.

“Our sensor uses weak electric fields to sense objects, even at a distance, much as touchscreens do,” said John Madden, electrical and computer engineering professor who heads the Advanced Materials and Process Engineering Laboratory at UBC.

“But unlike touchscreens, this sensor is supple and can detect forces into and along its surface. This unique combination is key to adoption of the technology for robots that are in contact with people.”

Sarwar said the breakthrough on the robot skin is three-fold.

First, the sensors are multiple mode, able to detect not just pressure, but horizontal movement as well, which gives them the ability to detect movement, like slipping.

Most sensors currently used in robotics or prosthetics just sense pressure, Sarwar said. Without the ability to sense horizonal movement, a prosthetic hand that picks up an egg may either apply too much pressure, and crush it, or too little, and drop it.

“If they even have any kind of sensing, it’s only pressure sensing,” Sarwar said. “It does not enable amputees to do any kind of dexterous manipulation because they can’t sense something is slipping.”

The second breakthrough was being able to embed these multiple mode sensors inside a silicone "skin." Finally, it’s relatively cheap to make.

“The fabrication process uses readily available material, and the fabrication steps are very simple process that require very low capital costs," Sarwar said. "So it’s easy to scale if we go into manufacturing."